Processing of Cereals, Grains

Milling

- Wheat, rice, corn, oats: commonly processed cereal grains

- De-hulled, ground into smaller pieces or flours

- To improve palatability

- Reduce cooking time

- Create food products

Removes outer hull which contains tough, fibrous material. Grains are revealed; can be toasted, soaked, or cooked to soften and release starch and carbohydrates.

Commodity crops

- Corn and soybeans: increasing demand as both animal and human foods; profitable in price

- Rice: relatively stable production last 20 years; not a dietary staple in the US

- Wheat: spike in prices

But what are commodity crops?

-

Wheat, Corn, Rice, Oats, Cotton, soybeans

- Can be easily traded

- Stored for a long time

- Grown in large quantities

-

Example, when you think of cotton you don’t ask where it’s grown or what year it was harvested - it’s just “cotton”. That’s what a commodity crop is

Storage and Distribution

- Commodity crops; long shelf life when kept cool and dry

- At 70F: dried grains, beans last over 10 years

- Minimum energy needed to store products

- Since perishability is not an issue, slow, cheap, transportation methods are used

Wheat kernel or seed:

- Endosperm: 83% of the grain; typically used in refined bread flower

- Bran: Rich in fiber, vitamins & minerals

- Germ: vitamins, minerals, fat, protein

Steps in Wheat Milling

- Olden days millstones replaced today with rollers

- Separate the bran, germ, and endosperm layers

- Endosperm layer - starch or flour

- Separate the bran, germ, and endosperm layers

- Final milling by-product is wheat shorts

- Consist of bran, germ, flour and tailings

- Used to be for cattle feed only

- Consist of bran, germ, flour and tailings

- Now, the bran, germ marketed as “Viable health food”

Fatty acids in germ contribute to off-flavors and rancidity, it is removed; storage time of white flour improved when compared to wheat flour

Bleaching and maturing of flour

-

*Final stage in the production of white flour

-

FDA approved use of agents

- Nitrogen trichloride, nitrogen tetroxide, chlorine dioxied, benzyl peroxide, acetone peroxides, azodicarbonamide

-

WHY?

- Fresh milled, unbleached flour - yellowish due to natral pigments in wheat

- Fresh milled flour - yields small, coarse-textured loaf

-

Solution: store the flour for several months to lighten color, improve baking qualities

-

FDA approved agents - similar effects in short period of time

-

Commerically made white bread, made from bleached flour, was considered a modern food and was more expensive than whole wheat bread

-

White bread was favored; a status symbol

-

1920s: wonder bread - with 12 vitamins, minerals - heavily advertised as healthy food for children

-

Today, whole wheat bread is more expensive than white bread; changing dynamics of food technology, nutrition and science on food choices

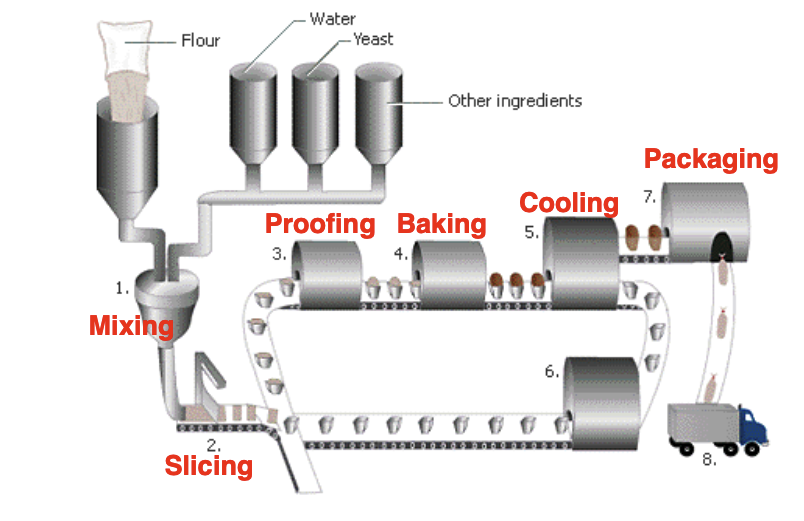

Bread production

- Ingredient mixing and dough development

- Automatic dough slicing and depositing into bread pans/trays

- Proofing / second rise

- Baking the loaves in hot-air convection oven

- Cooling the bread, separating the loaves from the bread pans

- Slicing and packaging

- Delivery to retail outlets

Products from corn

- Sweeteners: glucose, dextrose, corn syrup, high fructose corn syrup

- Oils, feed, meal, fiber foods

- Modified corn starch: thickeners in foods

- Ethanol: fuel and beverage alcohol

Dry milling corn

- The dry milling process requires the miller to remove the corn hull and germ without reducing the endosperm

- This process produces flaking grits, meals, flours, oil

- Breakfast cereal is produced from large flaking grits

Rice

-

Has traveled from China to India/Pakistan to Africa to Middle East, to Europe, finally arriving in South Carolina

-

Labor-intensive crop; utilized slave labor

-

Rice is typically consumed in kernel form

-

Outside rice hull - inedible; used for fuel or mulch

-

Brown rice: rice with outer bran layer

-

White rice: bran removed

-

**One of the most protected global agricultural commodities

Broken rice

- During milling, rice often breaks - broken rice

- Not as valuable as unbroken rice; used by processors, cereal manufacturers and pet food manufacturers

Soybeans

-

The two major products from soybean processing are high-protein meal and oil.

-

Food uses of oil include shortening, margarine, and cooking and salad oils; nonfood uses include paint, varnish, resins, and plastics

-

Soybean meal, which is the largest product produced from this process, is used by the feed industry as a protein supplement.

-

Bean family; primarily used for:

- Livestock feed

- Vegetable oil (80% of oil consumed in US)

Once beans reach the processors

- Processed directly into products made from whole soybeans - soymilk, flour, tofu

- Further refining: clean, dry, crack the hull form soybean

- Hulls go for animal feed

- Remaining portion converted into animal food flakes and soy flour

- Flakes: used to extract soybean oil and lecithin

- Lecithin: widely used emulsifier in salad dressings, mayonnaise, ice cream…

Oats

Steel Cut Oats

- Whole grains is cut into several pieces

- Longest to cook

- Toothsome, chewy texture

Rolled oats

- Whole grains first steamed then pressed to flatten them

- Cook faster than steel-cut oats

Instant Oats

- Most processed

- Whole grains pre-cooked, dried, and then rolled and pressed thinner

- Cook more quickly