Processing of Fruits & Vegetables

-

Companies in this industry use freezing, canning, dehydrating, and pickling to preserve fruits and vegetables.

-

Major US based companies: Kraft Heinz, JR Simplot, and Pinnacle Foods & divisions of large food companies such as ConAgra and General Mills

-

Bonduelle (France); AGRANA (Austria); Del Monte Pacific (Singapore), McCain Foods (Canada); Pinguin (Belgium); La Doria (Italy)

-

The major processed crops in the US are tomatoes (solid tomato and tomato paste products)

-

Potatoes (French fries, potato chips); and oranges (orange juice)

-

Corn; cucumbers (pickles); beans; grapefruit; apples (apple juice, applesauce); grapes (raisins); pineapples; peaches

-

The two major types of operations are canning and freezing. Canned goods and frozen foods each account for about 45% of industry revenue; dried foods account for about 10%

Why are fruits and Vegetables crisp?

- Turgor pressure:

- Vacuoles in cells filled with water; pressure is exerted on the cytoplasm and partially elastic cell wall

- RAW F & V prior to harvesting is crisp; because of large %age of water from the plant

- After “pickled”: water is lost to air, with evaporation or low humidity storage: loss of turgor pressure

- F & V wilt, limp, dehydrated

- If the paranechyma cell is still intact, water may reenter: Soaking rehydrates

Harvested vegetables are alive

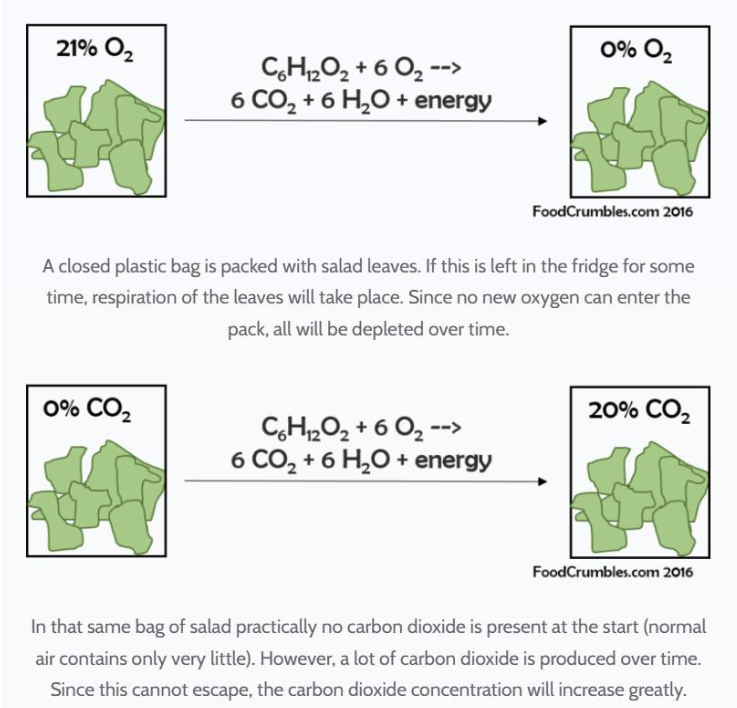

- The trick to storing vegetables for a long period of time is thus to keep respiration going for as long as possible. This can be done by slowing down respiration as much as possible (without stopping it)

- One way to slow down respiration is by controlling the levels of oxygen and carbon dioxide

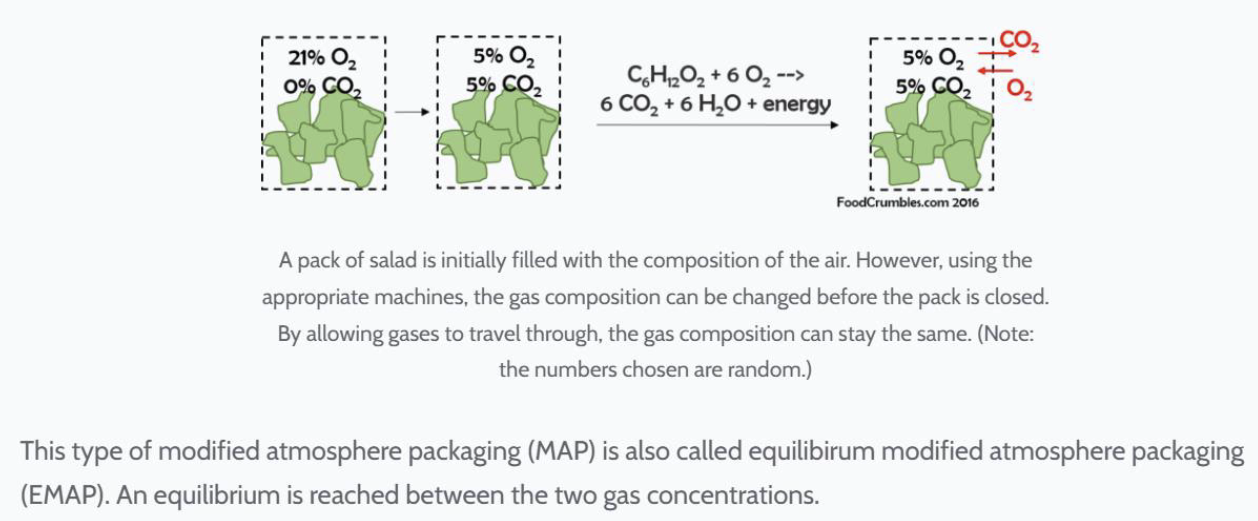

Designing MAP

- Ideally, a pack of vegetables should be designed in such a way that the optimal gas concentration is stable and exactly that which is best for the product

- Three main gasses used in MAP are C02, O2, and N2. The choice of gas is very dependent upon the food product being packed

What is ripening?

-

Fruits aren’t very appetizing when they’re unripe, they’re not as sweet and soft

-

Only when fruits have gone through their ripening process they’ll develop their appealing flavor and texture characteristics. Ripening is the final stage in growth.

-

If ethylene is not controlled post-harvest losses occur significantly

-

One of the common method farmers do to prevent post-harvest losses is harvest the produce unripe, and then artificially ripen it by spraying ethylene.

- This allows farmers to transport their produce at the optimum freshness and quality

- This is especially true for produce meant for long-term storage

-

The FDA has approved the use of ethylene as a commercial ripening agent.

-

In general, low temperatures slow down metabolism, and this includes ethylene production in plant tissues. This is the reason why it is ideal to store the produce at chilling temperature

Bananas

- Bananas are harvest when they’re still green and unripe.

- Pears are special because they are best harvested unripe, ripening on the tree will even decrease their quality due to stoniness.

- Control of ethylene gas after plucking extends the life cycle of the fruit / vegetable. Ethylene control enables warehouse owners not only to preserve freshness and reduce spoilage but also allows them to meet increasing demands for non-seasonal fruits and vegetables

Juices - why heat juices?

-

Pasteurization, unlike sterilization, doesn’t kill off all the micro-organisms in orange juice. Especially, spores will survive. These spores are very resistant to heat treatment. However, these generally do not grow at the pH of orange juice. Therefore, pasteurization is good enough for stabilization of orange juice for a couple months

-

Another common trick is that the orange juice is de-aerated, which will take out the oxygen of the juice.

-

Consumers tend to think that clear, unclouded OJ has been watered down or lacks freshness

-

Homogenization: This is a special process for making cloudy juice, usually for products packaged into bottles. During this process, the particles contained in juice are further crushed into smaller size, where pectin ooze out and disperse into the orange juice homogeneously. BY these means, we get cloudy juice

To keep juice clear, you remove starches and pectin

What is fruit juice and fruit juice concentrate?

-

Juice Concentrate

- Whole fruits are thoroughly washed, scrubbed, and crushed or blended to produce a pulp.

- Most of the water content is then extracted and evaporated

-

‘From concentrate’ means that all the excess water from the oranges is removed, yielding a product seven times more concentrated than the initial juice

- Compressing and then freezing the orange juice allows more efficient packaging and transportation

- Water is then added in again before it is sold

-

Juice ‘From Concentrate’ means that the juice was dehydrated, shipped to a factory, rehydrated, and packages.

-

Benzoates + sorbates used in combination with low temperatures to extend the shelf life of minimally processed juice drinks

-

The term **“no preservation added” has the false connotation of improved quality

-

Some pasteurized juices have a biting aftertaste due to excessive benzoate. The overuse is not harmful, but ironically completely unnecessary in adequately pasteurized juice. The philosophy, “if a little is good, more is better” has no place in food processing. Under no circumstances should any preservative be a substitute for sanitary practices”